- Operating Forklift with Safety Considerations

- Forklift Safety Training

- Safety Tips for Operating Forklift

- Forklift Safety Instructions

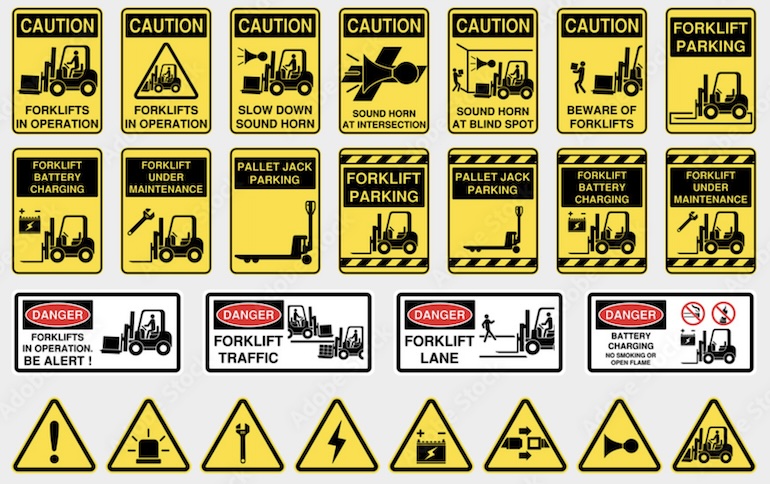

- Forklift Safety Signs

- Safety Checklist

- General Info

- Conditions at the Workplace

- Machine Parts

- Forklift Drivers

- Operating System

- OSHA Safety Rules for Forklift Drivers

- Pedestrian Safety Measures During Forklift Operation

- Forklift Safety Cage

- Conclusion

Forklifts are one of the powerful industrial machines that can lift and move heavy loads from one place to another, within the working areas. Mostly, they are used in industries and factories. While operating these machines, safety plays a very important role or else, the results can lead to injury or death. Well planned forklift training that not only explains safety rules, but also exposes the trainees to real time scenarios, can help to reduce accidents related to forklifts. Many instances of forklift accidents have been reported to National Traumatic Occupational Fatalities Surveillance Systems. Nearly, more than 1500 workers died due to forklift related accidents.

These accidents caused due to reasons like:

- Slipping off an operating forklift

- Hit or crushed by forklifts

- Overturned forklifts

OSHA demands the employers to ensure that they hire trained and skilled forklift operators. The operators need to be well-versed with physics and scientific principles in order to control the machine in safety terms. Operators need to keep the working area environment in mind while operating the machine. They should be cautious and never leave the machines unattended while the power is still on.

Operating Forklift with Safety Considerations

A forklift operator should be aware of every possible scenario that can arise while operating a forklift. Also, the operator should know how to deal with such situations. The machine might appear smaller but when fully loaded, there is no surprise that it weighs as much as a school bus. The following are the safety considerations one must check before operating a forklift. If any defects are found, ensure that they are rectified and repaired before you start with operating the machine.

- Check for any leakage of fluids especially near the fittings, before starting with the operation. If the fluid gets onto the tires, the machine might lose its grip and slide over the area, losing its control.

- Find if there are any loose bolts

- Ensure that the warning light is in working condition.

- Check if there are any cracks or bends in the steel.

- Also find if there are any small puddles on the floor.

- Examine hydraulic lines to find if there are any splits in the hose. When a line bursts while operating the machine, severe injuries can be caused to the operator.

- Check for owner’s manual to get an awareness on fluid reservoirs and their recommended levels for safe operation.

- Check if the brake pedals and lift are functioning properly.

Forklift Safety Training

OSHA determined safety rules, tips and warnings that every forklift operator should follow in order to ensure safety. Any forklift operator needs to bow before these regulations at any cost and also, update knowledge regularly to match with any new additions or changes.

These regulations that every operator requires are codified by OSHA under 29 CFR 1910.178(1). Except forklifts or trucks used in agricultural operations, every other areas that demand for forklift needs to be operated by certified operators.

Some of such areas include construction, shipyards etc. The validity of the certification is up to 2 to 3 years. Hence, the operator needs to refresh knowledge periodically by attending trainings regularly to again enjoy the presence of certification validity.

If the operator is held to be responsible for any fatal accident or a near miss accident then, the operator needs to attend more trainings if management demands. Also, if OSHA includes any new safety measures with time, then the forklift operators need to attend such trainings to match the skills with latest updates. The courses cover various areas that need to be satisfied with forklift operation like:

- Moral

- Ethical

- Legal

- Psychological

- Social

Apart from these, safety training also includes safety hazards, safety controls, stability triangle or trapezoid, center of gravity for both load and forklift etc.

Safety Tips for Operating Forklift

According to OSHA, numerous forklift accidents are recorded every year. These include both minor and major injuries that are sometimes fatal, and also property damages. Some of the precautionary steps to follow in order to ensure safety forklift operation are discussed below:

- Operate the machine only after you cross 18 years.

- Check for fluid levels, steel breaks, loose parts etc. before you start operating the machine.

- Make a test drive for a small distance to ensure that the pre-checks you made for the machine are correct.

- Use seatbelt, protective gear, helmet and safety glasses while driving.

- Ensure that you do not block the vision by overloading the truck. This rule should satisfy both normal and reverse driving.

- Make use of a spotter to ensure safe operation during reverse traveling.

- If you are under medication and taking drugs that make you feel drowsy then, do not attempt to operate the machine.

- Do not take alcohol before you operate the powerful machine.

- Never smoke while driving as it might lead to distraction or may catch fire.

- Do not use headphones, cell phones or watch videos while driving as it might lead to distraction.

- Do not overload the machine such that it crosses the capacity limit and loses control.

- Also do not tilt forward while elevating the load. This causes the machine to tip over.

Safety Tips While Forklift is Not in Operation:

- When the machine is not in use, lower the forks.

- Turn off the engine.

- Do not park the machine in areas where it turns to be an obstacle for others near stairways, exits or entrances.

- Turn on the parking brake for the machine.

Forklift Safety Instructions

Forklift safety guidelines are very important to ensure that there is minimum or no scope for injuries to both the operators and the pedestrians. Safety instructions play a very important role in reducing accidents that lead to minor or major injuries, property damage, stock damage, equipment damage, forklift damage etc.

Sometimes, when forklift crosses its pre-determined limits, the machine loses its control and tilts. In such cases, the engine is explored to high stress, and the life of the machine reduces. If you operate the machine within the specified limits, you can expect good durability and reliability for the machine.

Also, if the machine loses its control, accidents might occur and the pedestrian’s life can turn to be fatal. The machine is so powerful that when it dashes the walls or stairs, they might get damaged. Even the stock loaded in the machine and the load stored in the workplace can be damaged. To avoid such mishaps, it is recommended to operate the machine within the safety limits.

Forklift Safety Signs

Special safety signs are designed for operating forklift machines. These signs are warnings and indicators. Every forklift operator needs to be aware of these signs and should know how to deal with the signs.

Every place that needs to be attended should be addressed with respective safety signs so that the operator knows how to move forward with the forklift driving. Also, forklift operators can be reminded every now and then about the importance of safety operation.

These signs are generally marked in various sizes depending on the workplace nature. The operator should be in a position to see the sign clearly. The driver needs to be cautious and mindful of industrial machinery so as to avoid accidents or mishaps at the workplace. Even the pedestrians should be alerted with signs that warn them about the forklift existence.

Safety Checklist

With forklift safety checklist, one can ensure the safety condition of the machine. It helps to rectify if any problem exists. The checklist involves the checking of the machine details in various areas. The answers for the machine are either YES or NO. Also, a remark column is added to work on the comments. Some of the elements in forklift safety checklist includes the following:

General Info

- Workplace name

- Department

- Area where it is operated

- Forklift identification details

- Brief description of type of work

Conditions at the Workplace

- Operating area and walkers are clearly separated or not?

- Workers are not allowed to cross forklift pathways or not?

- Do the blind spots include mirrors or not?

- Are all the safety signs properly working or not?

Machine Parts

- Do the power specifications meet the requirement?

- Safety elements like seat belt, helmet, protective gloves, safety shoes, eye goggles etc. are provided or not?

- Maximum limit details for speed and capacity are provided or not?

- Does the brakes, horn, lights, indicators, reversing horn etc. operate properly or not?

- Maintenance of the machine is done regularly or not?

- Are pre-check details, maintenance details and safety elements details properly recorded or not?

- Are the fluid levels, brakes, steering, gear controls, tire pressures, batteries, fuel, mirrors, indicators, gauges etc. are up to the mark or not?

Forklift Drivers

- Is the operator skilled, trained and certified or not?

- Are the drivers attending regular trainings to update knowledge to the latest changes or not?

- Are the drivers attending appropriate trainings or not?

- Are the drivers understanding the importance of certifications, trainings, safety measures and load charts?

- Are the drivers checked for alcohol intake before attempting to start the machine?

- Are the drivers in good health condition?

- Is the driver aware of all the safety measures, fluid limits, power controls, speed and capacity limits etc.?

- Is the driver aware of the workplace layout?

Operating System

- Are the schedules planned to match the safety limits of forklift operation?

- Are the administration and monitoring systems implementing work while following safety measures?

- Are any uncertified or unskilled drivers operating the machine?

- Are safety measures followed during loading and unloading?

- Are the ramps, turns, docks, floor openings etc. marked to operate the forklift from defined distance from them?

OSHA Safety Rules for Forklift Drivers

Forklifts make the life of industrial workers easier in moving the heavy loads from one place to another. Without these machines, huge man power is required and at the same time, lot of time is wasted.

Therefore, it is a good idea to make use of forklifts in industries for efficient transfer of heavy loads from one place to another. However, operating them requires the forklift operators to follow a number of safety rules defined by OSHA. Rules are defined based on every scenario. Every time an unexpected and unusual or unique scenario arises, OSHA considers them and defines new safety regulations or even changes existing regulations as required.

Therefore, the operators need to be updated with the new and edited safety regulations regularly. If these rules are violated then, the industry is responsible for the mishap and might need to bear the fine charges.

Sometimes, the company might even lose the license for operating the forklift in their working premises. Therefore, regular caution is must and the company must hire separate team to monitor if proper precautionary steps, safety measures are taken or not. Also, the team should ensure that the forklift drivers follow the regulations at every step of forklift operation, whether it is at operation or when being parked.

Pedestrian Safety Measures During Forklift Operation

A number of pedestrians undergo accidents and injuries due to forklifts when proper safety measures are not taken to ensure safety for pedestrians in the working premises. These machines are highly powerful and humans cannot fight against such machines during fatal incidents.

The accidents can turn to be fatal for many of them by leaving them disabled for their life time. Sometimes, the mishaps even lead to death. Therefore, even the pedestrians should be made aware of the risks, injuries and fatalities that can be caused by forklifts.

Some of the accidents include crushing the pedestrians amidst hard objects, running of pedestrian’s feet, load falling over the pedestrian when not properly stored in the machine etc.

Pedestrians should be educated about the warning signs, cautious mind at workplace and the importance of visibility for the machine. Both the employees and the employers will be facing problems when a mishap is encountered due to these machines. Therefore, pedestrian training should be made compulsory and they should be updated with regular changes made by OSHA for pedestrians.

Forklift Safety Cage

A forklift safety cage is used when the employees perform work at elevated levels. OSHA defined safety regulations for a safety cage operation in forklifts. Some of them are discussed below:

- The safety cage needs to be constructed to hold not more than two persons or heavy tools.

- The safety cage gate needs to be designed with an open that directs only inwards.

- The moment gates shut, a spring tension latch is used to hold the cage along with its load in a secure manner.

- The floor in the cage needs to be made of a material that gives proper friction to the feet of the occupants.

- Proper safety pins should be used to attach the safety cage to the fork of the machine.

- The load of the cage should not exceed the determined limits at any cost. The load not includes persons, but also includes various tools and equipment carried along with them into the cage.

- The platform that holds both the cage and the occupants should be secured safely with appropriate measures.

Conclusion

Forklifts need to be operated with absolute safety precautionary measures and at any cost, the safety measures should not be compromised. Appropriate safety regulations are defined by OSHA for every type of forklift operation that range from forklift safety signals to pedestrians and safety forklift cage operation.

At every stage, respective safety guidelines should be followed or else, the mishaps can turn to be fatal for the operator and even for the pedestrians. A number of reported deaths are recorded with forklift operation.

If any driver or pedestrian violates the regulations defined by OSHA, the company would be held responsible for the mishap and will be needed to bear the fine expenses. Sometimes, even the license can be cancelled. Therefore, the companies should hire only skilled, trained and certified forklift operators to ensure proper functioning of the working system.