The eDumper dump truck (Komatsu HB 605-7) is the largest electric vehicle in the world. The eDumper, made by Kuhn Schweiz, it’s based on a Komatsu HB 605-7, it’s 30 feet long, 14 feet wide, and 14 feet tall. The tires are six feet high, and the dump bed reaches over 28 feet when it’s fully raised. With a 600-kilowatt-hour battery pack, all of the truck’s energy is stored in its lithium electric battery which weighs around 5 tons.

For years, companies have relied on heavy machinery — almost all of which burns gas and diesel — to expose ore, minerals, and other materials from beneath the earth’s surface and turn it into usable components. One company, Kuhn Schweiz AG, has found a way to do at least part of that work completely emissions-free, together with researchers from the Bern University of Applied Sciences in Bern, Switzerland and the NTB Interstate University of Technology in Buchs, Switzerland.

The world’s largest electric vehicle with an empty weight of 58 tons and a payload of 65 tons has been christened «Lynx» on April 20 2018 in the presence of numerous representatives from business and politics and will start its work next week in the quarry of Vigier Ciment in the Canton of Berne. The electric dump truck designed over the past 18 months is an example of successful applied research in Switzerland. This interdisciplinary cooperation has set three world records.

The eDumper is the largest and most powerful battery-powered electric wheeled vehicle in the world. For this purpose, the largest battery ever produced for an electric vehicle was installed. Never before has a comparable vehicle been able to save such a large amount of CO2. The eDumper will transport more than 300,000 tons of rock per year over the next 10 years. According to preliminary calculations, the vehicle will save up to 1,300 tons of CO2 and 500,000 litres of diesel over the next 10 years. eDumper ascends a 13% grade and can take on 65 tons while doing so.

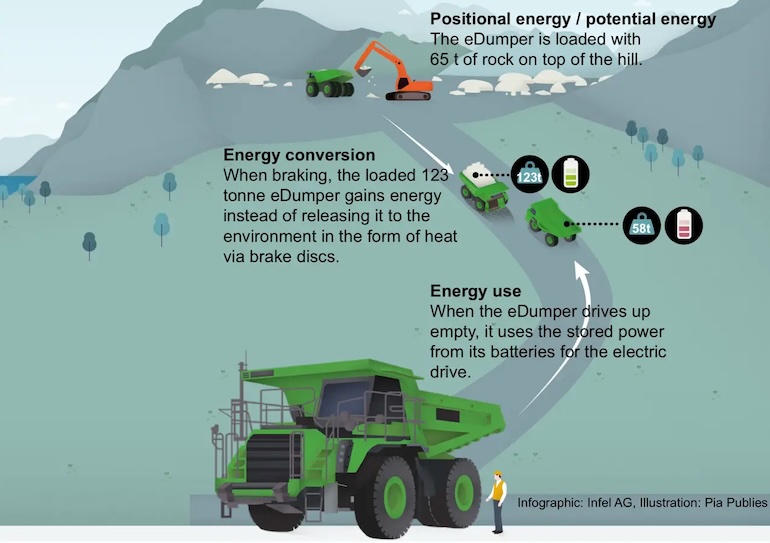

The eDumper will transport lime and marl rocks from a higher mining area to a lower processing plant. During the fully loaded descent, the batteries are charged by recuperation of braking energy. According to preliminary calculations, the electricity generated in this way is largely sufficient for the empty return journey uphill to the mining area. Thus, the vehicle would be a zero-energy vehicle. The exact energy balance of the eDumper will be shown by investigations in everyday operation over the next few months. The eDumper is expected to move some 300,000 tons of rock every year for the next decade.

Kuhn Schweiz says, the eDumper produces 200 kWh of surplus energy every day, or 77 megawatt-hours a year. A typical dump truck uses between 11,000 and 22,000 gallons of diesel fuel per year. Which means that saves up to 196 metric tons of carbon dioxide every year! «To ensure the fire safety of such a large battery cell, the Swiss Federal Laboratories for Materials Science and Technology Empa examined the behavior of the Li-Ion cells used in the event of a short circuit or mechanical damage. Never before has a land vehicle been equipped with such a huge battery pack. The eDumper is now designed in such a way that a failing cell cannot affect neighbouring cells,» a press release says.